Rosin is a common impurity residue in the production process of pcba circuit board, and its main sources usually include the content of the material itself, which is polluted during the manufacturing process. In the use of pcba circuit boards, rosin may adversely affect the function of the circuit board, resulting in abnormalities in the pcba circuit board. Therefore, cleaning the rosin on the circuit board is crucial.

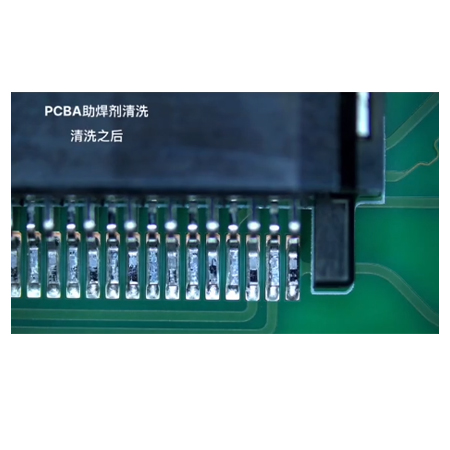

Before and after cleaning

Bt-800p circuit board cleaning equipment is specially designed for soldering flux cleaning after wave soldering, replacing manual cleaning to improve cleaning capacity and cleanliness, and reduce cleaning costs; Automatic cleaning mode, to avoid the operator contact with chemical liquid; Mainly used in military, aviation, aerospace electronics, medical, automotive new energy, automotive and other coating products and high-end precision products cleaning a variety of products, small batch PCBA board cleaning, can effectively clean SMT/THT PCBA welding surface residual rossine flux, water-soluble flux, no-clean type flux/solder paste and other organic and inorganic pollutants; • Cleaning of poorly printed PCB board solder paste, scraper solder paste cleaning, etc. Bt-800p off-line PCBA cleaning machine, automatic cleaning mode: When the equipment is running, the workpiece moves back and forth in the cleaning basket with the cleaning basket, while the spraying system high-pressure jet heated cleaning liquid, which can make PCBA get automatic cleaning, rinsing, drying the whole process.

In short, for the rosin flux residue of the pcba circuit board, selecting the appropriate cleaning solution and the correct operation method can make the cleaning more effective, and it is also necessary to pay attention to prevent damage to the pcba circuit board. You can select the appropriate cleaning equipment and cleaning agent according to the actual situation.