Process flow:

The gas is separated into plasma state by excitation power supply -- the plasma acts on the surface of the product -- cleaning the contaminants on the surface of the product -- improving the surface activity and enhancing the adhesion property.

Plasma cleaning is a new, environmentally friendly, efficient and stable surface treatment method.

Field of Application:

• Mobile phone industry: TP, middle frame, back cover surface cleaning activation;

•PCB/FPC industry: in-hole drilling and surface cleaning,Coverlay surface coarsening and cleaning;

• Semiconductor industry: Semiconductor packaging, camera module,LED packaging,BGA packaging,Wire Bond preprocessing;

• Ceramics: packaging, dispensing pre-treatment;

• Surface coarsing etching: PI surface coarsing,PPS etching, semiconductor silicon wafer PN junction removal,ITO film etching;

• Plastic materials :Teflon Teflon surface activation,ABS surface activation, and other plastic materials cleaning activation;

• Clean the surface before ITO coating.

Equipment features:

• Flexible product placement fixture, can adapt to irregular products;

• Horizontal electrode design to meet the needs of soft product handling;

• Low energy consumption gas products;

• Convenient way of retracting and releasing board;

• Integrated vacuum system, small footprint;

• Reasonable plasma reaction space, so that the treatment is more unifom;

• Integrated control system design to make operation more convenient.

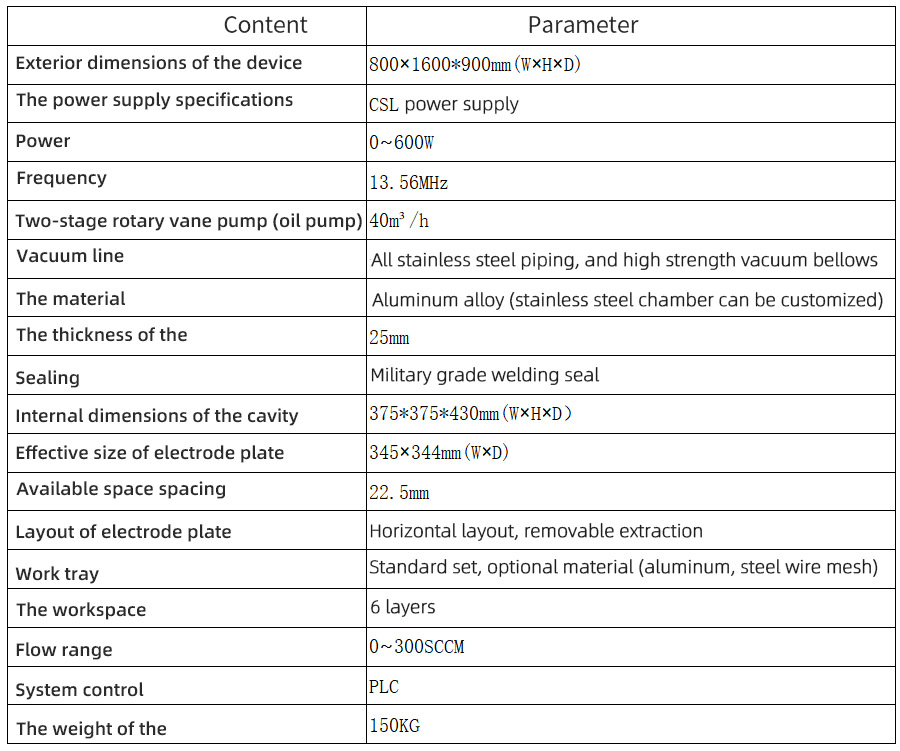

Technical parameters: