The process flow:

Manually put into the net plate - the net plate is thrown up and down - the spray pump pressurized online centralized filtration cleaning - recovery liquid - the spray pump pressurized online centralized filtration rinsing - Air cut drying - manual out of the screen.

Application field:

Bpt-1000x automatic water-based screen cleaning machine is a fast cleaning, cleaning integration, compact structure of environmental protection cleaning equipment.

Applied TO: SMT steel mesh, copper mesh, rubber mesh, printing glue fixture,PCB error board cleaning, can effectively clean the residual surface and hole wall after printing, solder paste, red glue and other contaminants.

Steel net class The bronze class PCB/PCBA Printing scraper class

Characteristics of the equipment:

• Automatic cleaning mode: the screen up and down casting, while spraying system high pressure spray heating cleaning liquid, can make the full range of automatic cleaning, rinsing, drying the whole process;

• Visualization of the whole process: visual window and LED light device make the cleaning process clear at a glance;

• The most scientific nozzle design (patent) : the use of left and right 8 spray arm distribution - completely solve the cleaning blind area, spray arm, nozzle detachable;

• The visual nozzle pressure can be adjusted: it solves the problem of collision and splashing of small size workpiece under high pressure spray during cleaning;

• Photoelectric sensors are installed at the observation window and the entrance of the screen to protect personal safety. The standard diluent tank/rinsing tank heating system greatly improves cleaning efficiency and reduces cleaning time;

• Comprehensive cleaning system: compatible with running water washing or chemical cleaning for SMT; Residual rosin, water-soluble flux, non-cleaning type on the surface of THT PCBA after welding

• Clean organic and inorganic contaminants such as flux/solder paste thoroughly and effectively;

• Body material: 304 stainless steel body, acid, alkaline and other cleaning fluid resistance;

• Cleaning the built-in filter device can realize solvent recycling and reduce solvent consumption;

• Emergency stop button and leakage protection function in case of solid barrier;

• Lower operating costs: lower equipment investment costs, localized service teams and adequate supply of spare parts.

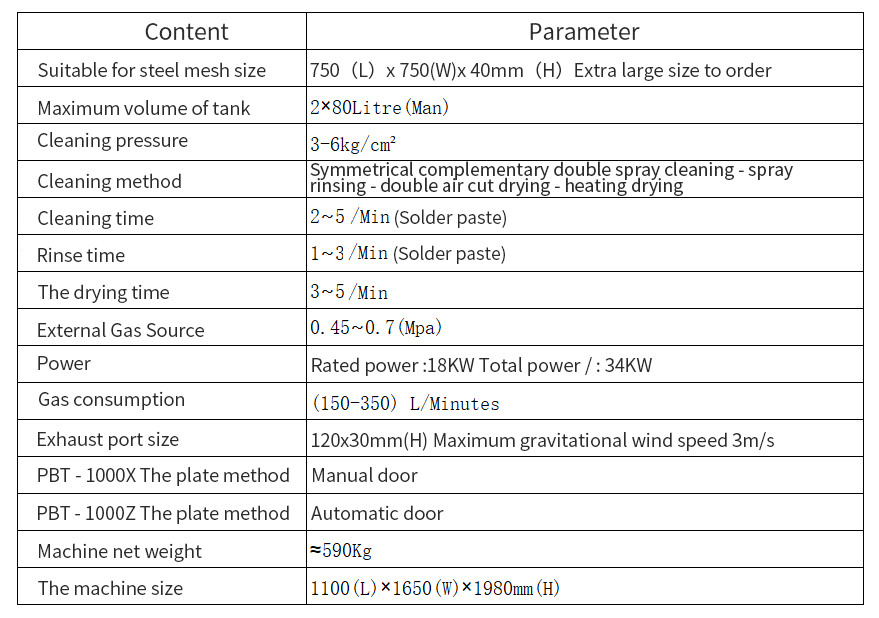

Technical parameters: